CANADA BLOWER

PRODUCTS

Propeller Fan Products

Canada Blower industrial regenerative side channel blowers, forward curved pressure blowers and fans in stainless steel, alloy, cast aluminum, cast iron, polypropylene and FRP construction. Canada Blower, Chicago supplies replacement forward curved blowers and wheels for forward curved blowers and fans manufactured by Buffalo Blower - New York, Twin City Fan, Northern Blower, Chicago Blower, Sheldons, Cincinnati Fan, Hartzell, IAP, Industrial air products, Canadian blower, Aerovent, Penn Ventilation, Penn-Barry, Barry Blower, ACME, Aerovent, Alphair, American Fan, Lau Industries, Clarage, Delhi, Canarm, Leader Fan, Daltec, ABB, Flakt, Flaktwoods, Woods, MK Plastics, Robinson Industrial, Garden City Fan, Loren Cook, Jen-air, Jenn Fan, Aeroflo, Grainger, Greenheck, Kice Fan, ILG Industries, Canada Fan, Industrial Air, Ceilcote, Solar and Palau, Strobic air, Trane, TCF Axial.PROPELLER WALL FANS

Fans and blowers are built in larger sizes, smaller sizes and with performance capabilities other than the standard ventilator models listed are available. Custom fan modifications can also be supplied for unique applications.

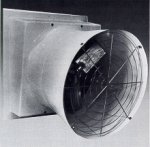

Type CBC Propeller Fans

A general ventilation fan designed for efficiency and economy.

Suggested for use in commercial and industrial applications including factories, warehouses, gymnasiums, underground parking garages or any area requiring ventilation where side wall mounted fans are desirable.

Type CBC fans are rugged and dependable. They are available in a large selection of CFMs and pressures.

The fans can be arranged for exhaust or supply ventilation use.

A wide choice of fan accessories are available to complete a well-balanced and specifically engineered air movement system.

A direct drive general Type CBU Propeller Fan designed for use in commercial and industrial ventilating applications where low sound levels are important and relatively low CMFs are appropriate.

Type CBCD fans combine the durable construction and reliability needed for industrial applications with the quietness and good looks required for office or laboratory. They offer the low maintenance requirements that are characteristic of direct drive fans.

By combining the Type CBCD fan with a companion wall sleeve and other accessories, a ready-to-mount wall ventilation package is provided.

The Type CBCD fan may be assembled for air exhaust or supply usage.

CBCA - Belt Drive: 4,000 to 30,000 CFM

0" to 1" Static Pressure

CBCX - Belt Drive: 20,000 to 60,000 CFM

to 1" Static Pressure

CBC / CBCL - BELT DRIVEN WALL PROPELLER FANS

CBC - Belt Drive: 15,000 to 120,000 CFM

to 1" Static Pressure

CBCL - Belt Drive: 10,000 to 60,000 CFM

to 1" Static Pressure

CBCD - DIRECT DRIVE WALL PROPELLER FANS

Belt Drive: 1500 to 61500 CFM

to 1.5" Static Pressure

CBCA WALL PROPELLER FANS

CBCA - Belt Drive: 3,000 to 30,000 CFM

to 0.25" Static Pressure

CBU / CBP - DIRECT DRIVE WALL PROPELLER FANS

CBU - Direct Drive: 500 to 7,000 CFM

to 0.5" Static Pressure

CBP - Direct Drive: 250 to 3,500 CFM

to 0.5" Static Pressure

UPBLAST ROOF FANS

Type CBJ PRV fans are suggested for use in commercial and industrial applications including factories, warehouses, commercial buildings, machine rooms or any situation requiring the movement of air.

Type CBJT PRVs are suggested for use in industrial applications where it is necessary for the fan assembly to be located above the roof and where motor, belts and bearings must be isolated from the airstream. (Type CBJTB)

Canada Blower Co. upblast power roof ventilators are designed for long life, low maintenance and all-weather fan performance.

The proven upblast design is the most cost effective roof exhauster built today and offers the best value of all PRV fan types.

With many commercial and industrial buildings such as factories, warehouses, parking garages, shopping malls and department stores a means of venting hot gases and smoke in the event of a fire is required.

Type CBHS PRVs are especially designed, built and proven by independent test to meet this essential need. They reliably extract large volumes of hot gases and smoke regardless of building configuration, location or weather conditions. They withstand high temperatures for long periods.

A reliable fan ventilation system that can operate during a fire is both vital and essential. It prevents smoke logging, allows people to escape quickly, minimizes damages to property and contents and enables firemen to attack the fire without hindrance.

These PRV ventilators have the added advantage of providing normal day-to-day ventilation and in many cases can also be fitted with ductwork for use in multi-story buildings.

The unique Type CBHS power roof ventilator concept provides a solution for emergency heat and smoke venting that is dependable under the most extreme circumstances.

CBJH - Belt Drive: 6,000 to 30,000 CFM

to 0.5" Static Pressure

CBJX - Belt Drive: 25,000 to 60,000 CFM

to 0.5" Static Pressure

CBJ - BELT DRIVE AXIAL ROOF VENTILATORS

CBJ - Belt Drive: 20,000 to 120,000 CFM

to 1" Static Pressure

CBJD DIRECT DRIVE AXIAL ROOF VENTILATORS

CBJD - Belt Drive: 2,000 to 60,000 CFM

to 1" Static Pressure

CBJT / CBJTB BELT DRIVE AXIAL ROOF VENTILATORS

CBJT - Belt Drive: 2,000 to 100,000 CFM

to 1" Static Pressure

CBJTB - Belt Drive: 2,000 to 50,000 CFM

to 1.5" Static Pressure

CBJTD DIRECT DRIVE AXIAL ROOF VENTILATORS

CBJTD - Belt Drive: 2,500 to 65,000 CFM

to 1" Static Pressure

AXIAL DUCT FANS

It is suggested for commercial and industrial uses such as make-up air systems, booster fans, return air fans or to exhaust contaminated or high temperature air.

Type T fans are available in a large selection of CFMs and operate efficiently against static pressures up to 2 inches.

A true vane axial Type CBV fan designed for use in a wide range of commercial or industrial applications.

High pressure efficiency permits the fan to be installed anywhere in the system; in any position. It can be used for either supply or exhaust by simply turning the entire fan unit to flow air in the desired direction.

Type V fans are extremely compact and well suited to locations where space is limited. In many instances, these fans are mounted directly to the duct work.

As a result of very close tolerances and carefully matched vanes and rotor, the Type V fan offers exceptional performance within its ventilator size range.

CBT - Belt Drive: 1,500 to 100,000 CFM

to 2" Static Pressure

CBTE - Belt Drive: 2,500 to 50,000 CFM

to 1.5" Static Pressure

CBTD - DIRECT DRIVE AXIAL DUCT FANS

CBTD - Direct Drive: 1,500 to 80,000 CFM

to 2" Static Pressure

CBVD / CBVB - DIRECT AND BELT DRIVE VANE AXIAL DUCT FANS

CBV - Direct Drive: 250 to 7,000 CFM

to 2" Static Pressure

HOODED ROOF FANS

These fans are suggested for use in commercial and industrial applications including factories, warehouses and large commercial buildings.

These rugged ventilators PRVs are available in a broad range of CMFs and a variety of configurations.

There are types offering belt and direct driven propellers, exhaust, supply or reversible are movement, and filtered air supply.

Most hooded PRVs can be supplied less fan component for use as a gravity ventilator or as an air intake.

At a later date this unit can be converted to a power roof ventilator by simply installing the proper style Buffalo Fan Co. Type C Fan.

Combinations of these various types can be used and still maintain a uniform and attractive rooftop ventilator appearance.

Use of the power combination of hooded power roof ventilators assures an effective ventilation system at exceptionally low cost.

Type CBRE and CBRS fan recirculators are multi-purpose power roof ventilators.

These ventilators are suggested for use in commercial and industrial applications where there is sufficient ceiling height to create a temperature differential between the floor and ceiling.

These ventilation applications include factories, warehouses and large commercial buildings.

Type CBRE and CBRES recirculators function as normal power roof ventilators in warmer weather and as an energy saving recirculation system in cold weather.

Each unit is equipped with a reversible fan wheel that redistributes warm ceiling air throughout the plant and reduces the building's heating requirement. WIth the flip of a switch, it can function as a conventional roof ventilator.

CBD - Exhaust - Direct Drive: 3,000 to 40,000 CFM

to 1" Static Pressure

CBPE / CBPS - BELT DRIVE EXHAUST SUPPLY AXIAL ROOF VENTILATORS

CBPEB - Exhaust - Belt Drive: 4,000 to 95,000 CFM

to 1" Static Pressure

CBPS - Supply - Belt Drive: 3,500 to 100,000 CFM

to 1" Static Pressure

CBRE / CBRS-BELT DRIVE TWO WAY-THREE WAY-FOUR WAY AXIAL POWER ROOF VENTILATORS

CBRE - Exhaust / Recirculator - Belt Drive: 4,500 to 50,000 CFM

to 0.5" Static Pressure

CBRS - Exhaust / Supply / Recirculator - Belt Drive: 2,500 to 40,000 CFM

to 0.5" Static Pressure

CBRD / CBRSD-DIRECT DRIVE TWO WAY-THREE WAY-FOUR WAY AXIAL POWER ROOF VENTILATORS

CBRD - Exhaust / Recirculator - Direct Drive: 4,500 to 50,000 CFM

to 0.5" Static Pressure

CBRSD - Exhaust / Supply / Recirculator - Direct Drive: 2,500 to 40,000 CFM

to 0.5" Static Pressure

CBHS - Belt Drive: 2,500 to 100,000 CFM

to 1" Static Pressure

CBHSE - Belt Drive: 1,750 to 50,00 CFM

to 1" Static Pressure

CBPT - 3,500 to 30,000 CFM

CBFG - 2,000 to 12,000 CFM

CBN - 10,000 to 20,000 CFM

to 0.2" Static Pressure

CBM - 11,000 CFM

CBM - Exhaust Belt Drive- 4,000 to 30,000 CFM, to 0.5" Static Pressure