AIR HANDLING FANS - AXIAL

BELT and DIRECT-DRIVE

Capacities to 150,000 CFM, 14" SP

Airfoil centrifugal fan wheel in inline-flow configuration for high pressure systems and quiet operation. Non overloading horsepower characteristic and inherent fan stability when used in systems requiring varying air volumes.

BELT and DIRECT-DRIVE

Capacities to 100,000 CFM, 2" SP

Steel axial wheels for low pressure ventilation and industrial process applications. Duct, Tubeaxial, and Vaneaxial Fans are available in 15 sizes with wheel designs selected to optimize performance across each line.

BELT and DIRECT-DRIVE

Capacities to 120,000 CFM, 3.5" SP

Cast aluminum airfoil fan wheels for moderate pressure ventilation and industrial process applications. Duct, Tubeaxial, and Vaneaxial Fans are available in five mounting arrangements to meet a wide range of installation requirements.

BELT and DIRECT-DRIVE

Capacities to 150,000 CFM, 7" SP

Cast aluminum wheels with airfoil blades for high pressure ventilation and industrial-process applications. Direct-drive fans feature wheels available at specific blade angles to maximize performance.

Capacities to 80,000 CFM, 1.5" SP

Available as exhaust or supply fans, explosion proof, with

automatic or motorized shutters, guards, weather hoods and other

ventilator accessories.

Capacities to 100,000 CFM, 2" SP

15 diferent fan sizes; available as exhaust or supply fans, spark-resistant, with automatic or motorized fan shutters, guards, weather hoods and other ventilator accessories.

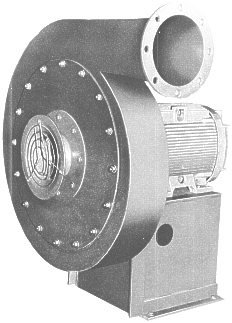

AIR HANDLING FANS - CENTRIFUGAL BLOWERS

Capacities to 200,000 CFM, 15" SP

Complete AMCA Class I, II, II performance. Efficiencies beyond 85%, with direct or belt driven fan arrangements. Choice of Airfoil, Backward Inclined Flat-Blade or Backward Curved blades, in 18 sizes: 12" through 85" wheel diameters. Operating temperatures to 800 degrees F.

Capacities to 350,000 CFM, 14" SP

Double-Width Airfoil fans combine the efficiency of Canada

Blower's airfoil wheels with construction features to suit industrial

supply and exhaust systems as well as HVAC applications. A wide range

of accessories is available to tailor the fans to each unique

application. Complete AMCA Class I, II, II performance; with

efficiencies beyond 85%.

Capacities to 200,000 CFM, 50" SP

A heavier-duty extension of the Class I, II, III SISW Fan Line designs for higher pressure requirements. Choice of two wheels for best efficiency: airfoil for clean, dry airstreams or flat blade BI fan wheel for moderate amounts of dirt and moisture, temperatures to 800 degrees F.

Capacities to 250,000 CFM, 40" SP

Backwardly curved wheel design for high efficiency with non-overloading fan horsepower characteristic, featuring curves which cover a wide range of narrow-width performance at direct-drive motor speeds. Suitable to higher horsepowers required for high pressure blower performance.

Capacities to 5,000 CFM, 60" SP

Furnished in direct-drive Arrangement 4 with wheel mounted on motor shaft for low-volume, high-pressure process requirements. Efficient aluminum impellers for highest efficiency and lowest noise level, steel wheels available for temperatures to 800 degree F and light dust conditions. Also available in Arrangements 1, 8, and Arrangement 9, 10 packaged designs.

Capacities to 15,000 CFM, 140" SP

HPPB Pressure Blowers are designed for high pressure, industrial process applications. All applications can be handled in either induce-draft or force-draft blower configurations. Numerous modifications and accessories make the Type HPPB Pressure Blower suitable for a wide range of systems.

Capacities to 40,000 CFM, 12" SP

Arrangement 10 packaged design reduces field labor and allows for test-running before shipment; choice of ventilator wheels for best efficiency: Airfoil fan wheel for clean, dry airstreams or flat-blade BI wheel for moderate amounts of dirt and moisture; with accessories and modifications include weather cover/belt guard, spark-resistant / explosion proof, and heat-fan construction for operation up to 650 degrees F.

Capacities to 7,000 CFM, 3" SP

Used for clean dry airstreams. Arrangement 4 direct drive and Arrangement 10 belt drive packaged fans with forward-curve wheels for quiet operation in general ventilation or simple process exhaust. ome belt-drive sizes available with heat-fan construction to 500 degrees F.

Capacities to 20,000 CFM, 3" SP

Arrangement 10 packaged design for general ventilation, with

choice of wheels: airfoil for clean, dry air or falt BI for moderate

amounts of

dirt and moisture. Accessories and fan modifications include weather

cover/belt

guard, outlet shutter, spark-resistant ventilator construction, etc...

DUST AND MATERIAL HANDLING FANS

Capacities to 75,000 CFM, 20" SP

Available with paddle and radial-curved fan wheels, with emphasis on packaged designs to factory assembly / test run of fan, motor, drive - to reduces costly field labor and allows test-running prior to shipment. Temperatures to 1000 degrees F.

Capacities to 100,000 CFM, 30" SP

Available with varios versions of radial blower wheel, heavy industrial construction for long operating life in high-pressure and material-conveying blower systems. Available in both belt drive and direct drive fan arrangements. Operating temperatures to 1000 degrees F.

Capacities to 150,000 CFM, 50" SP

Available with paddle or radial curved blower wheel, which is particularly advantageous in high-pressure process systems to hold horsepower requirements to a minimum. Naroow-width fan construction available for easy selection for direct-drive that is frequently desirable for higher horsepowers required at high pressures. Temperatures to 1000 degrees F.

Capacities to 3,000 CFM, 20" SP

Small radial blade blowers with radial backplated wheels for low-CFM material handling applications, in direct-drive and belt-drive arrangements. Airstream temperatures to 600 degrees F.

Capacities to 200,000 CFM, 30" SP

Radial tip wheel design for light-to-moderate loading of dust, dirt, powder or flakes, available wear plates for handling abrasive particulate. Belt-driven and direct-driven arrangements with evase for maximum efficiency. Operating temperatures to 800 degrees F.

Capacities to 300,000 CFM, 70" SP

Radial Tip impeller design for light dust and dirt loading in medium volume, high pressure blower applications. Available with outlet dampers, evases, inlet boxes, and silencers often required in high-pressure applications. Air-flow temperatures to 1000 degrees F.

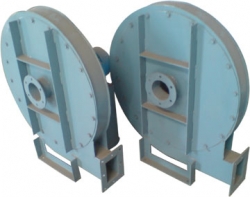

FIBERGLASS FANS

Fiberglass Pressure Blowers

Capacities to 8,000 CFM, 40" SP

Radial blade wheel design suited to chemical process and air pollution control systems when corrosion resistance and high static pressures are required. Direct-drive and belt-drive arrangements.

Capacities to 15,000 CFM, 14" SP

Radial-blade wheel design for low air volumes in applications varying from laboratory fume hoods to highly corrosive chemical processes. Packaged Arrangements 4 and 10 for easy installation and maintenance.

Capacities to 30,000 CFM, 10" SP

Backwardly inclined wheels for efficient air performance and

non-overloading horsepower characteristic. Arrangements 9 and 10 fan /

motor /drive packages reduces field assembly labor. Various accessories

such as weather cover / belt guard, access door, drain, companion

flanges, fan dampers are available.

Capacities to 100,000 CFM, 20" SP

Backwardly inclined fan wheels for efficient air performance and non overloading horsepower characteristic. Available in low-pressure or high-pressure configuration, in Fan Arrangements 1, 8, 9, and 10, to match system requirements.

SPECIAL PURPOSE PRODUCTS

Operating temperatures to 2,200 degress F.

Oven circulating or free-standing housed super high

temperature fans

an centrifugal or axial flow ventilator design. Water cooled shafts on

direct-fan

arrangements,

as well as water cooled motors are available.

High pressure blowers in series (both centrifugal and positive

displacement / side channel) to generate extremely high pressure,

including high temperature fan applications.

.

Capacities to 140,000 CFM, 12" SP

Airfoil Plenum Fans are designed specifically for application in pressurized plenums found in industrial and commercial air handling units. Their un-housed, compact design combined with the airfoil wheel provides the utmost in efficient and dependable operation.

Capacities to 100,000 CFM, 20" SP

Choice of forward curved, radial, airdoil or backwardly inclined fan wheel in plug pan configuration for industrial oven and dryer applications. Insulated fan panel protects bearing and motor. Available without insulation for low temperature cabinet ventilator units, for temperatures to 1,800 degrees F.

Capacities to 100,000 CFM, 6" SP

Forward curved blower wheels in one or two fan, housing, shaft, and bearing combinations, designed to suit a wide range of air performance, temperature, and fan dimensional requirements; greatl for use in ovens, dryers, air-handlers, and built-up plenum systems. Operating emperatures to 1000 degrees F.